KITT4SME invited SMEs and midcaps from the AI-developer community with a proposition for the manufacturing industry to join the project and gain access to technical know-how and the chance to create ‘success stories’ for their solutions through the project’s pilot experiments. 53 proposals were submitted to the Type-B Open Call, and 7 of them were selected for funding with a total of €1.318.622 awarded to the winners.

DMV had the pleasure of being one of the winners of this competition with its FASPAS proposal, together with its partner VIRTUONA. More about this you can find on the link:

https://kitt4sme.eu/awarded-proposals-of-type-b-second-open-call/

FASPAS

(Fatigue aware semantics for planning and scheduling in discrete manufacturing)

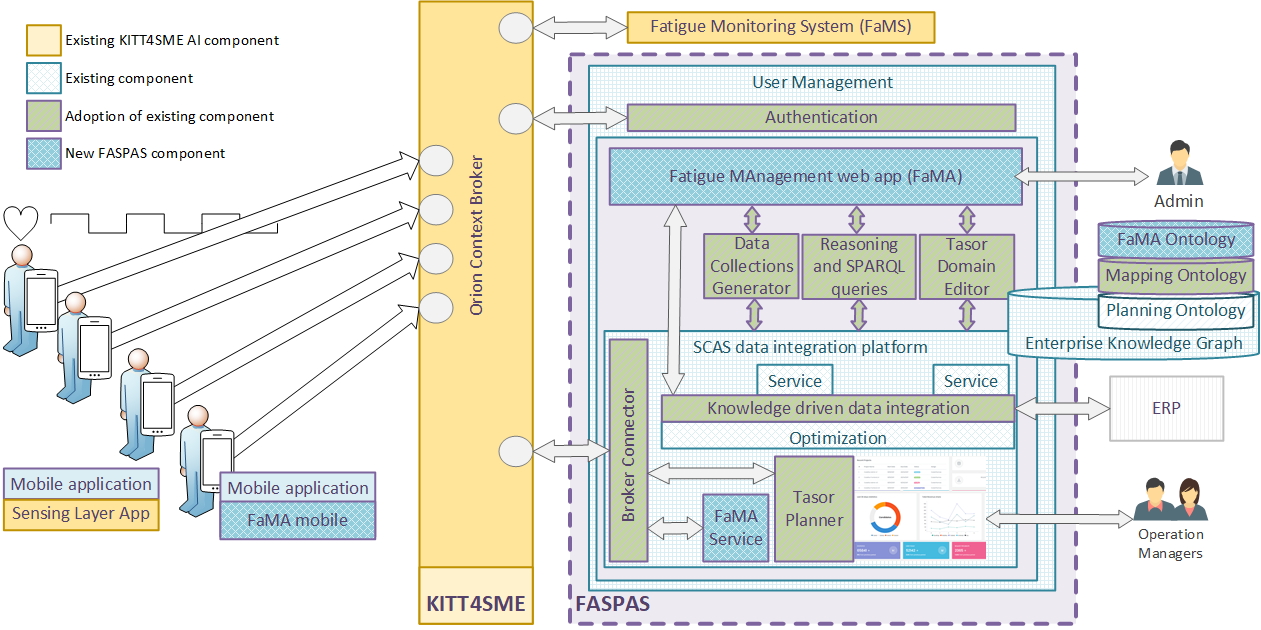

FASPAS addresses the challenge of scaling up the number of work orders in a discrete manufacturing environment by leveraging automatic generation of plans and schedules. The aim is to optimize manufacturing operation as well as workforce in mass production of heterogeneous custom products. When dynamic aspects such as physiological state and fatigue of employee are taken into consideration the problem becomes even more challenging. Main benefits include cost reduction, reliable commitments to customers, improved production throughput as well as higher job satisfaction level in the workplace. In order to integrate all aspects of the problem, FASPAS semantically annotates data from FaMS, an AI-based KITT4SME component, that analyzes physiological data indicating fatigue acquired by wearable devices (such as blood pressure, heart rate, galvanic skin response) together with static characteristics (skills, age, work experience and similar). The semantically annotated datasets will be used for semantics-based reasoning in order to perform optimal work order planning and scheduling taking into account all relevant factors.

FASPAS system architecture and components

According to targeted objectives, some of business related drivers could be structured as follows:

- Value and number of tasks per unit of time – should be used as a measure of overall operation efficiency

- Employee positive attitude and satisfaction – measure of probability of injuries and employee turnover rate

- Fulfillment rate of the norm time – measured by a percentage with respect to historical data